Elon Musk’s dream of colonizing Mars in a handful of years is bold but probably misbegotten. He means well in wanting to safeguard the survival of the human species, but things may not end well. There’s no reason for humans to be out there just yet. It might work out best if Musk’s large-scale plans crater and his still-sizable contributions (e.g., reusable rockets) remain. We can explore space for the foreseeable future without the undue burdens of cost and loss of life if we utilize robots for reconnaissance and 3D printers to lay foundation.

In “The Low-Tech Way to Colonize Mars,” an Atlantic piece by Sarah Zhang, the writer examines a saner alternative to Musk’s vision, a slow build in space via bootstrapping with relatively simple tools. An excerpt:

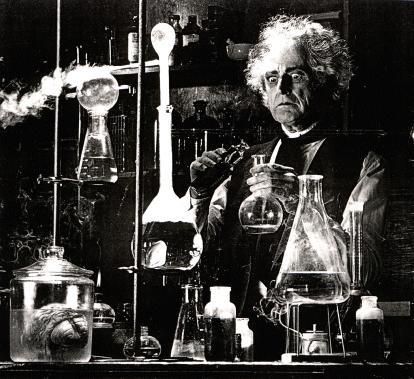

NASA is all aboard the 3D-printing train. Last year, it unveiled winners of its first 3D-printed Mars habitat design challenge, and the architectural renders of the winning entries were all sleek and futuristic, as renders of unbuilt buildings always are (see above). In reality, the current state of the art for Martian 3D-printing looks more like the clay logs [planetary scientist Philip] Metzger has been documenting on Twitter.

If the technology looks low-tech, it’s deliberate. “We’re rethinking how to do space technology by taking cues from less developed parts of world,” says Metzger. The logic goes like this: If a valve breaks in a complex machine on Mars, an astronaut can’t go online to order a replacement with next day delivery. (It’s more like nine months, assuming Mars and Earth are in their most favorable alignment.) So the idea is to start simple and slowly build up technological capabilities: clay to metal to plastic to electronic equipment. Eventually, Mars will have the refineries and factories to make complicated machines itself. This is “bootstrapping,” and it’s Metzger’s vision for space exploration.•